Technology

“Time is money”

Another confirmation of a proverb is applied in automation and standardising graphic production through investment in new technologies.

Hrastić Mediaprint- Printing with its powerful technological and technical operations also meets all the requirements imposed by the above phrase.

Production is divided into three main sectors:

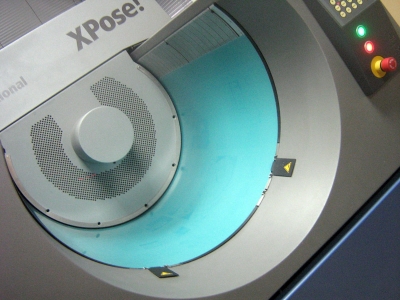

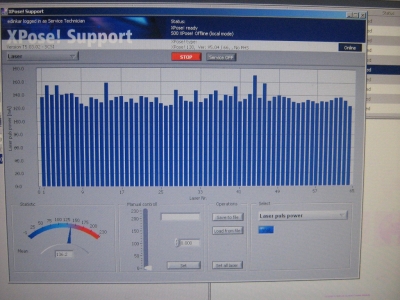

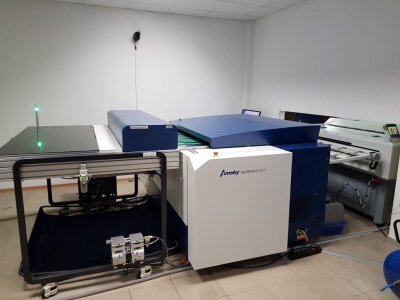

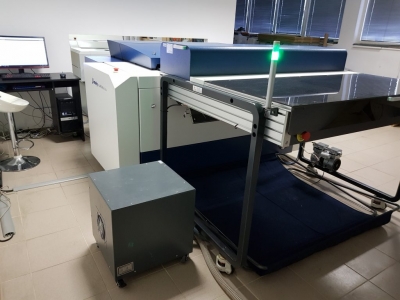

PRODUCTION OF PRINTING FORMS CTcP

Luescher XPOSE! 130 UV CTP device for illuminating conventional offset plates in B1 format, speed up to 20 B1 plates per hour, Harlequin RIP 8.02, 2400 dpi

Preps software for electronic assembly

HP Compaq workstation

Lastra Machine for automatic development of offset plates

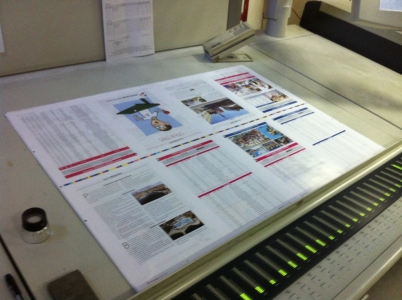

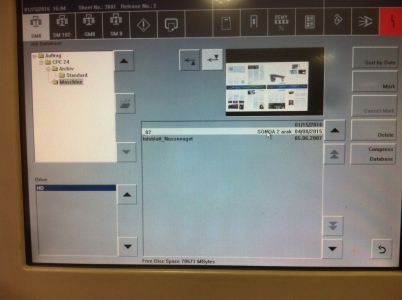

Heidelberg Speedmaster 102-8P eight-coloured printing machine with the possibility of reversing sheets 4/4 (full color printing in a single pass) and CPC 24 IMAGE CONTROL unit for full control of the printing quality

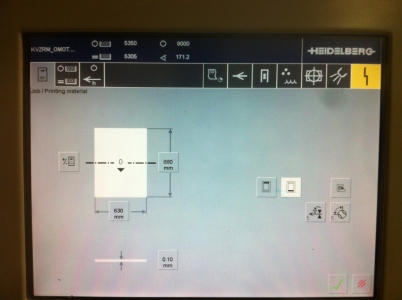

CP 2000 Center for digital control of all functions of the machine

Autoplate Plus (fully automatic update of printing forms)

Preset automatic change of the paper in the feeder and delivery apparatus

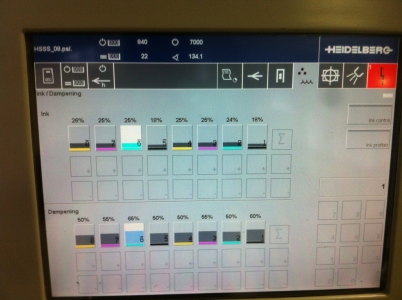

CIP 3 online input of data from the CTP preparation in a machine and presetting colouration areas

Max speed up to 13,000 sheets per hour

The formats from 32 x 45 cm to 72 x 102 cm

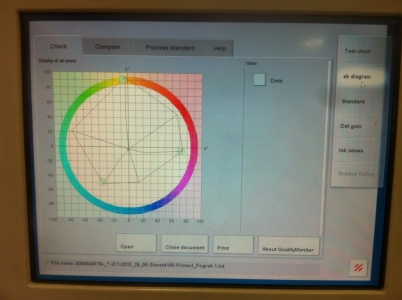

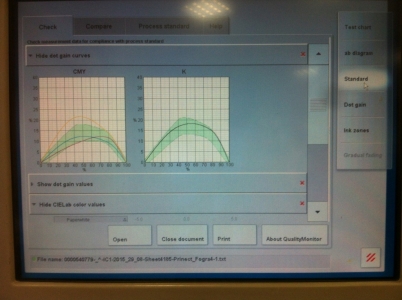

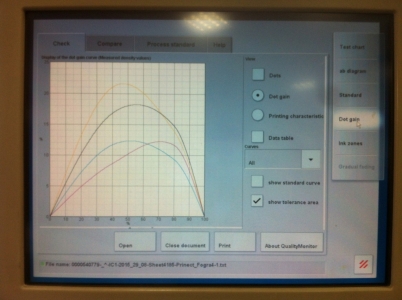

Spectrophotometric control of printed sheets is performed with a device Heidelberg CPC 24 IMAGE CONTROL, where, in a period of 20 seconds, the laser reads the entire printed colour sheets to 3 million measurable pixels and does an on-line correction of colouration intensity in the printing press according to set parameters using density standard DIN 16536th

In the module Prinect Quality Monitor diagrams of deviation from the colouration standard are presented, deformation raster dots through growth (dot gain), in color after printing zones by default tolerance etc.

BINDERY

Muller Martini 321 machine for wire stapling with 6 book blocks and cover feeder, the control of the length, height and obliquity of invested sheets, Klamer quality control, max format 32 x 40 cm, the device for cross-presentation of stacked products, speed up to 10,000 copies per hour.

Heidelberg KH 78-4 KZRL machine for bending sheets with pallet feeder Tremat, SBP 46D press for pressing bent sheets, the ability to bend up to 32 pages, airstream investment, electronic knives 4 ×, VGA touchscreen for machine functions control, bending speed up to 50,000 cycles per hour.

Stahl KC 66-6 KTL Folding machine with roto investment, SBP 46 press for pressing bent sheets, the possibility of bending to 4-16 pages, electonic knives for bending, bending speeds up to 40,000 cycles per hour.

Stahl K 66-4 KTL machine for bending sheets with pile feeder Tremat, the possibility of bending 4-16 pages, exhibition tables, bending speeds up to 20,000 cycles per hour.

Mailbag machine for inserting magazines in plastic bags.

Polar 115 EMC Monitor fast shearer with an elevator, air bags.

Cyklop Ampag machine for stacking with PE tape.

Delivery

Citroen Jumper 2.2 HDI delivery van